As the world accelerates toward a carbon-neutral future, the race to reinvent how we power transportation is entering a new chapter. For years, the spotlight has beamed squarely on electric vehicles (EVs) as the de facto solution to our fossil fuel addiction. Yet, the real energy revolution might be far more diverse. The internal combustion engine, long considered the villain of climate-conscious living, may still have a role to play—just with a cleaner, alternative fuels.

Alternative fuels refer to any fuels used in place of traditional gasoline or diesel that aim to reduce environmental harm and improve energy efficiency. This includes a wide array of options like Compressed Natural Gas (CNG), Liquefied Petroleum Gas (LPG), biofuels (such as ethanol and biodiesel), hydrogen, and even synthetic fuels—each with its own performance quirks and environmental trade-offs.

This article will unpack the true potential of these non-electric alternatives—exploring how they perform on the road, what impact they have on the planet, and the systemic shifts needed to make them viable at scale.

The Case for Alternative Fuels

Environmental Concerns

The case for rethinking vehicle fuel sources begins with an undeniable reality: gasoline and diesel are environmental liabilities. From tailpipe emissions to refinery waste, their impact stretches far beyond the gas station. These conventional fuels are major contributors to greenhouse gas emissions, spewing out carbon dioxide (CO₂), nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter that harm not only our climate but also the air we breathe.

As cities choke under smog and global temperatures climb, it’s no longer enough to focus on tailpipe regulations or cleaner refining. What we need are transformative solutions—fuels that emit fewer pollutants, degrade more cleanly, or burn more efficiently. Many alternative fuels meet these criteria, offering reduced CO₂ footprints and cleaner combustion profiles.

Energy Security

Beyond the environmental imperative lies the issue of energy sovereignty. Today’s energy infrastructure is heavily tethered to petroleum imports, subject to volatile pricing, political strife, and unpredictable global supply chains. This dependence has tangible consequences—economic, diplomatic, and strategic.

By embracing alternative fuels, especially those produced domestically or renewably, nations can decouple their economies from the geopolitics of oil. Biofuels made from agricultural waste, CNG sourced from natural gas reserves, and hydrogen produced via electrolysis all represent pathways to greater self-sufficiency and long-term stability.

Resource Availability

There’s another hard truth: fossil fuels are finite. They took millions of years to form and are being consumed at an unsustainable pace. As reserves dwindle and extraction costs rise, the urgency to identify viable, scalable replacements intensifies.

Many alternative fuels, by contrast, are abundant, renewable, or synthetically manufacturable. Ethanol, for example, can be distilled from corn or sugarcane. Biodiesel can be made from used cooking oil. Hydrogen, though energy-intensive to produce, is the most abundant element in the universe. These options represent not just short-term fixes but potential long-term successors in a post-petroleum world.

Performance Diversity

Lastly, the appeal of alternative fuels isn’t limited to sustainability—they can also unlock new performance paradigms. For instance, CNG and LPG deliver cleaner combustion with fewer particulates, making them ideal for city vehicles. Biofuels can be engineered to suit different engines or climates. Hydrogen fuel cells, though still in early adoption, offer rapid refueling and long range—a potential game-changer for heavy-duty fleets.

Rather than replacing gasoline and diesel with a single silver bullet, alternative fuels create a mosaic of solutions, each tuned for specific use cases—from urban commuting to cross-country logistics. This diversity is a strength, not a limitation.

Alternative Fuels: A Detailed Examination

Compressed Natural Gas (CNG)

Fuel Properties and Production

Compressed Natural Gas is primarily composed of methane (CH₄) and is stored under high pressure (typically around 3,000–3,600 psi). It is most commonly extracted from natural gas fields, though a growing portion can be sourced from biogas—organic waste decomposition via anaerobic digestion, which creates a renewable variant known as Renewable Natural Gas (RNG).

The environmental footprint of CNG varies: natural gas extraction (especially fracking) has notable methane leakage risks, a potent greenhouse gas, whereas RNG from landfills or farms turns waste into usable fuel with a reduced net carbon footprint.

Performance Characteristics

CNG boasts an octane rating of 120–130, making it highly knock-resistant and compatible with high-compression spark-ignition engines. However, its energy density is approximately 25% lower than gasoline, which translates into reduced range per tank.

Engines using CNG can deliver comparable power and torque but may suffer in acceleration due to fuel storage limits. Despite this, fuel efficiency is solid, and performance is reliable for urban fleets, light trucks, and delivery vans.

Tailpipe emissions from CNG vehicles are significantly lower, particularly in terms of CO₂, NOx, and particulate matter. CNG combustion produces 20–30% fewer greenhouse gas emissions than gasoline or diesel, and when derived from RNG, the reductions can be even more substantial—potentially carbon-neutral or negative.

Advantages

- Lower emissions (especially NOx and particulates)

- High octane value

- RNG is renewable and waste-derived

- Competitive fuel cost

- Compatible with modified gasoline engines

Disadvantages

- Lower energy density

- Large, heavy fuel tanks

- Limited refueling infrastructure

- Methane leakage concerns during extraction and transport

Current and Potential Applications

CNG is widely used in public transit, municipal vehicles, and fleet trucks. OEMs like Honda (with the now-discontinued Civic GX) and many commercial vehicle manufacturers have produced factory CNG options. It’s ideal for city logistics and fleets with centralized refueling. Ongoing research in solid-state methane storage could dramatically improve future viability.

Liquefied Petroleum Gas (LPG)

Fuel Properties and Production

LPG is a mixture of propane (C₃H₈) and butane (C₄H₁₀), both of which are byproducts of natural gas processing and crude oil refining. It’s stored in liquid form under moderate pressure, making it more compact than CNG and easier to transport.

Performance Characteristics

LPG has an octane rating between 105 and 110, supporting high-compression engines with fewer knocking issues. Its energy density is lower than gasoline by about 25%, yet its combustion characteristics result in smooth engine operation, with minimal deposits and longer engine life.

Fuel economy per gallon may be less favorable, but cost savings and engine longevity can offset this. Torque and power are generally slightly lower but within acceptable margins for everyday passenger cars.

Environmental Impact

LPG emits significantly less CO₂, NOx, and particulate matter than gasoline or diesel. It is clean-burning, helping reduce smog formation in urban areas. Lifecycle emissions are lower than gasoline, although not zero, as it remains a fossil-derived fuel.

Advantages

- Clean combustion and low emissions

- Existing infrastructure in many regions (Europe, Asia)

- Lower maintenance and longer engine life

- Moderate storage pressure and ease of transport

Disadvantages

- Still fossil fuel-based

- Lower energy content

- Specialized fuel tanks required

- Less range compared to gasoline

Current and Potential Applications

LPG is used extensively in taxis, delivery fleets, and passenger vehicles in markets like Turkey, South Korea, and Poland. It’s also favored in off-grid power generation and industrial applications. Future prospects hinge on bio-LPG—renewable propane produced from organic feedstocks.

Biofuels

Ethanol

Fuel Properties and Production

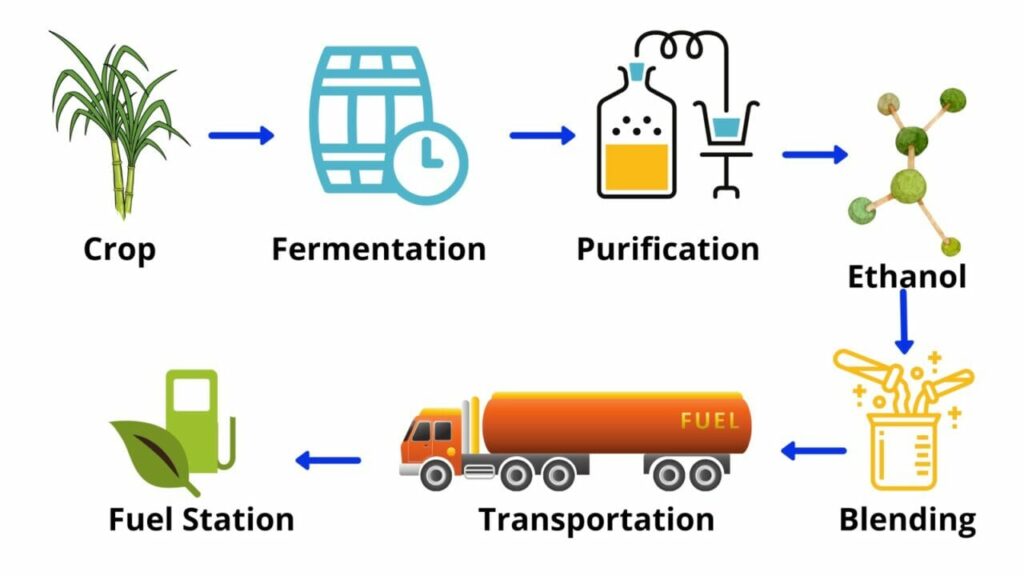

Ethanol is an alcohol-based fuel (C₂H₅OH) produced via fermentation of sugars found in corn, sugarcane, or cellulosic biomass (agricultural waste, switchgrass, etc.). Its energy inputs vary: corn ethanol has higher lifecycle emissions, while cellulosic ethanol is more sustainable.

Performance Characteristics

With an octane rating of 108+, ethanol supports high-compression engines, improving power and efficiency. However, its energy density is about 34% lower than gasoline, which reduces vehicle range unless used in optimized flex-fuel vehicles (FFVs).

Environmental Impact

Tailpipe CO₂ emissions are lower due to the carbon uptake of crops during growth, but total lifecycle emissions depend on land use, fertilizers, and energy input. Cellulosic ethanol presents the best environmental case with up to 85% GHG reduction.

Advantages

- Renewable, domestically produced

- High octane

- Compatible with flex-fuel vehicles

- Promotes rural economic development

Disadvantages

- Lower energy density

- “Food vs. fuel” debate

- Requires blending infrastructure

- Lifecycle sustainability varies widely

Current and Potential Applications

Ethanol is widely blended with gasoline (E10, E15, E85) in North America and Brazil. High ethanol blends (E85) are used in performance and fleet vehicles. Future research into algae- and waste-derived ethanol aims to eliminate food-crop dependency.

Biodiesel

Fuel Properties and Production

Biodiesel is made through transesterification of vegetable oils, animal fats, or algae into fatty acid methyl esters (FAME). It is biodegradable, non-toxic, and can be blended with petroleum diesel (B5, B20, B100).

Performance Characteristics

Biodiesel has a higher cetane rating (45–55) than standard diesel, improving combustion in compression-ignition engines. Its energy density is about 8–10% lower, which may marginally reduce power and fuel economy.

Environmental Impact

Biodiesel reduces CO₂, unburned hydrocarbons, and particulates, but can increase NOx without exhaust after-treatment. Lifecycle GHG emissions can be cut by up to 80%, particularly when made from waste oils or non-food crops.

Advantages

- Renewable and biodegradable

- Compatible with existing diesel engines

- Reduces tailpipe emissions

- Can use waste feedstocks

Disadvantages

- Cold-weather performance issues

- Feedstock availability and competition

- Slightly lower fuel economy

- Quality control concerns (especially for B100)

Current and Potential Applications

Common in municipal buses, commercial trucks, and agricultural equipment. It’s scalable for heavy-duty sectors, with expanding interest in algae-based biodiesel that avoids land use conflicts.

Hydrogen

Fuel Properties and Production

Hydrogen (H₂) is the simplest and lightest element, but rarely found in free form. It’s produced primarily through steam methane reforming (SMR) or electrolysis of water using electricity. The latter, when powered by renewables, yields “green hydrogen”, the cleanest variant.

Performance Characteristics

In fuel cell electric vehicles (FCEVs), hydrogen is converted to electricity to power electric motors. The result: instant torque, smooth acceleration, and long range. Hydrogen has high energy density by weight, but very low density by volume, requiring compression or liquefaction.

Environmental Impact

Hydrogen-powered vehicles emit only water vapor. However, 90% of hydrogen today is “grey,” produced from natural gas with CO₂ byproducts. Scaling up green hydrogen is critical for environmental impact parity with EVs.

Advantages

- Zero tailpipe emissions

- Fast refueling

- Long driving range

- Suitable for heavy-duty transport

Disadvantages

- Expensive production (especially green H₂)

- Difficult storage and transport

- Scarce refueling stations

- High infrastructure costs

Current and Potential Applications

Used in vehicles like the Toyota Mirai and Hyundai NEXO, and in pilot projects for hydrogen buses, trucks, and trains. Significant R&D focuses on liquid organic hydrogen carriers (LOHCs) and solid-state storage to overcome infrastructure barriers.

Performance Comparison

Alternative fuels often have lower energy densities than conventional fuels, impacting range and refueling frequency. However, high octane ratings in fuels like ethanol and CNG enable higher compression ratios and boost compatibility with turbocharged or high-performance engines. Biodiesel offers torque characteristics similar to diesel, but with slightly reduced energy content.

Hydrogen and electric powertrains (when considered as an alternative fuel system) provide superior efficiency and immediate torque, benefiting acceleration. However, their infrastructure and cost limitations currently hinder widespread high-performance deployment.

In short, while some alternative fuels may compromise on energy density or range, they can deliver impressive performance when paired with the right engine technologies—especially those optimized for high-octane combustion or electric drive systems.

Environmental Impact: A Broader Perspective

Tailpipe emissions alone don’t tell the full environmental story. A holistic “well-to-wheel” analysis—encompassing every stage from raw material extraction to final vehicle use—is essential to truly assess a fuel’s environmental footprint.

Traditional fuels like gasoline and diesel require significant energy for extraction and refining, generating substantial upstream emissions. Transporting these fuels also adds to their carbon cost. Ethanol and biodiesel, while renewable, demand large amounts of land, water, and energy during cultivation and processing. In some cases, biofuels may compete with food production, leading to deforestation or changes in land use that negate their carbon benefits.

First-generation biofuels (e.g., corn ethanol, soy biodiesel) can strain agricultural systems. However, second-generation biofuels, derived from non-food crops or agricultural waste, offer a more sustainable path. They reduce land competition and overall emissions, especially when cultivated using regenerative farming methods.

CNG and hydrogen require resource-intensive processes. While natural gas emits less CO₂ than gasoline, methane leakage during extraction and transport can offset its climate advantages. Hydrogen, especially when derived from fossil fuels (gray hydrogen), also has a considerable carbon footprint. However, when produced using renewable electricity (green hydrogen), its life-cycle emissions drop dramatically.

The holy grail for many alternative fuels is net-zero emissions. Biofuels from algae or waste, green hydrogen, and even synthetic e-fuels made with captured CO₂ could eventually provide carbon-neutral or even carbon-negative options.

Conclusion

Evaluating a fuel’s sustainability requires looking beyond the tailpipe. Well-to-wheel assessments allow policymakers, manufacturers, and consumers to make informed decisions that align with broader climate goals—helping prioritize fuels that offer genuine reductions in environmental impact across their entire lifecycle.